About the project

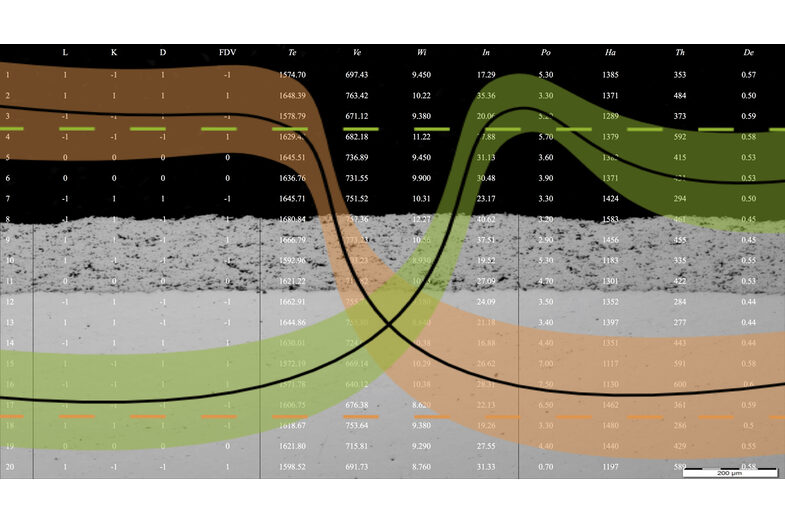

The aim of the project is to develop statistical methods for modelling, daily optimization, monitoring and control of thermal spray processes. The high-speed flame process for coating surfaces is characterized by high particle velocities, which results in coatings with high strength. A pioneering aspect of the project work is the measurement and use of particle properties in flight. This makes it possible to react to daily changes without the need for time-consuming measurements of the sprayed coatings. The project is a successful example of cooperation between statistics and mechanical engineering. Statistical research is being conducted into test plans, forecasting models and process optimization methods. Test plans are created in such a way that they provide the information required for statistical modeling with as few tests as possible. Models for expected values and covariance matrices of multiple quality characteristics are used to determine the cause-and-effect relationships between adjustable parameters and quality characteristics, taking uncertainty into account. Methods of robust process optimization then provide process settings in which the quality characteristics of the injection-moulded layer achieve the desired target values with minimal variation.

Sponsor

German Research Foundation (DFG)

German Research Foundation

https://gepris.dfg.de/gepris/projekt/140555865(Opens in a new tab)

Funding program / Research program

DFG Collaborative Research Centers

Collaborative Research Centers of the German Research Foundation

Cooperation/project partners

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, TU Dortmund, Faculty of Mechanical Engineering, Chair of Materials Technology; http://www.lwt.mb.tu-dortmund.de/cms/de/Lehrstuhl/index.html(Opens in a new tab)

Resources

Publications

Dette, H., Hoyden, L., Kuhnt, S., & Schorning, K. (2017), "Optimal designs for thermal spraying", Journal of the Royal Statistical Society, Ser. C, 66(1), 53-72

Erdbrügge, M., Kuhnt, S., & Rudak, N. (2011). Joint optimization of independent multiple responses. Quality and Reliability Engineering International, 27(5), 689-703.

Kirchhoff, D., Kuhnt, S., Bloch, L., & Müller, C. H. (2020). Detection of circlelike overlapping objects in thermal spray images. Quality and Reliability Engineering International.

Kuhnt, S., Rehage, A., Becker-Emden, C., Tillmann, W., & Hussong, B. (2016), "Residual analysis in generalized function-on-scalar regression for an HVOF spraying process", Quality and Reliability Engineering International, 32(6), 2139-2150

Kuhnt, S., & Rudak, N. (2013). Simultaneous Optimization of Multiple Responses with the R Package JOP. Journal of Statistical Software, 54(9), 1-23.

Kuhnt, S., Tillmann, W., Brinkhoff, A., & Becker-Emden, E.-C. (2019), "Durable machine parts: How statistical design of experiments optimizes wear protection", in Krämer, W., Weihs, C. (Eds.). Fascination Statistics, Springer, Berlin Heidelberg, 164-171

Rudak, N., Hussong, B., & Kuhnt, S. (2015). Simultaneous optimization of multiple correlated responses with application to a thermal spraying process. Quality and Reliability Engineering International, 31(7), 1223-1238.

Rudak, N., Kuhnt, S., & Riccomagno, E. (2014). Modeling of a Thermal Spraying Process by Gaussian Chain Graphs. Quality Technology & Quantitative Management, 11(1), 85-98.

Tillmann, W., Kuhnt, S., Hussong, B., Rehage, A., & Rudak, N. (2012). Introduction of a day effect estimator in order to improve the prediction of particle properties in an HVOF spraying jet. Thermal Spray Bulletin, 2, 132-139.

Contact & Team

Contact person and management

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann

M. Sc. Alexander Brinkhoff